ABUS EOT cranes at a producer of agricultural machinery in Germany

Agriculture through the ages

Looking back just 150 years and it becomes clear very quickly that agricultural business at the time meant hard physical work and working by hand. It was only through increasing industrialisation thanks to the invention of steam engines that agriculture saw industrial-mechanical processes introduced which lead to work-sharing production. Today agricultural production in farms of all sizes would not be possible without state-of-the-art specialist machinery for various applications.

Krone – the specialist for state-of-the-art forage harvesting equipment

Evolved from a rented smithy at Spelle in Lower Saxony the Krone group (www.krone.de) has been producing agricultural machinery for more than a 100 years. The complete range of Krone products includes disc mowers, rotary tedders and rakes, forage wagons, large square and round balers. The two self-propelled machineries BiG M and BiG X are also included in the Krone range. BiG M is a high-capacity mower conditioner with an impressive 13.20m work width. The forage harvester BiG X is presently the world’s most powerful farming machine. Krone offers the BiG X in different performance categories from 500 to over 1000 hp. Krone counts among the leading producers in the section of commercial trailers and agricultural machinery and is represented on all continents.

The new Krone logistics centre

Numerous machines and equipment leave the production plants of the Krone group every day—optimised logistics for worldwide dispatch are thus imperative for a company of this size. When an extension of the factory became necessary a new logistics centre was therefore included which opened at Spelle in May 2012. The total volume of investment amounted to 2.6 million Euros. The new building of 4,000 square metres includes four loading bays as well as a container handling facility. 20 to 30 trucks can be dispatched and up to 150 machines loaded on a daily basis. The new logistics centre is rounded of by a “DriversPoint” with modern break rooms for truck drivers and the Krone print office where order-specific manuals are printed.

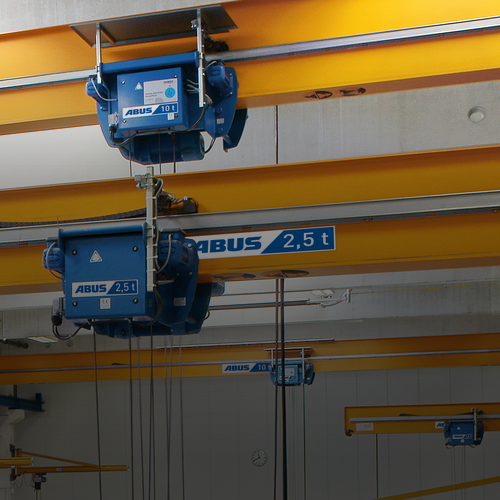

ABUS cranes for transport solutions

ABUS had good references when it came to be considered for the logistics centre: since 1986 ABUS Kransysteme had designed, delivered, and installed a total of almost 80 ABUS cranes, i.e. 41 jib cranes and 38 EOT cranes. The requirement was for cranes that would load farm machinery of up to 25 tonnes safely and very smoothly onto the trucks. ABUS won the tender offering a total package consisting of a two track crane runway and cranes in tandem operation. 4 double girder EOT cranes with 2 hoists of 8 tonnes each (double rail trolley type D) and a span of 26,600 mm were installed in the 115 metres long building as well as one single girder EOT crane of identical span and a lifting capacity of 6.3 tonnes. All cranes feature the ABULiner frequency converters for long and for cross travelling thus giving the cranes a maximum of positioning accuracy when loading the machines onto the trucks. The ABUS radio remote control installed on all cranes makes for smoother operating of the cranes and allows the crane user to carry out the loading of the trucks from a safe distance. The load suspended from the hook is displayed in the load display.

Looking forward with Krone agricultural machinery and ABUS cranes

Innovative technology can only be used efficiently if the staff or the user is trained properly. The Krone group has made it a habit for many years to carry out trainings for their customers. When the new logistics centre was officially opened the foundation stone for the new Krone training centre was laid. Two ABUS single girder EOT cranes with a load capacity of 3.2 tonnes and a span of 15.400 mm will be installed in the 102 metres long reinforced concrete building. ABUS will also supply the crane runway required in parts of the building.